Single-Sided Flashboard Risers have unique constraints that must be considered for successful installations.

Floating, Leaning and Sliding are important design factors that are often overlooked when installing single-sided flashboard riser structures.

Floating

Single-sided box-type flashboard inlet structures want to “float” when the water is blocked and the inlet box and outlet pipe are dry.

Leaning and Sliding

The weight of soil behind tall structures can push on the back causing the structure to lean forward and slide away from the bank. These factors are magnified in loose and soggy soil conditions where the soil slumps excessively.

Schematic diagrams of the forces acting on a single-sided flashboard riser box:

Single-Sided Flashboard Risers and the pipe will float if they are not anchored in place or sufficiently backfilled with dirt to hold them down.

Single-Sided Flashboard Risers will be pushed outward and forward by earth pressing against them.

All single-sided flashboard riser structures will encounter Floating, Leaning and Sliding Forces

The structures will resist floating, leaning and sliding to some degree through a combination of their weight and soil trapped against the sides and the pipe flange. These forces can become a significant problem on large and tall boxes.

Our DrainBox Flashboard Structures have features to manage floating, leaning and sliding forces.

The riser box has an extended base and provisions for pinning to help support the box and relieve stress on the pipe connection.

We offer support frames for tall boxes. When properly backfilled, these frames will control the floating forces and significantly reduce the tendency for the boxes to lean or slide. Support frames are supplied with all structures 48 inches and taller. The frames are easily assembled on site.

How Strong is the Floating Force on a Flashboard Riser?

Answer — Pretty Strong!

This is why we recommend using the smallest practical pipe size and we offer support frames for flashboard risers!

Real life example of a floating plastic pipe

This 12-inch plastic pipe was half-buried when it was inadvertently flooded. The pipe quickly floated and bent upward as shown here.

The hollow ribs on the double-wall corrugated pipe trap air. These air pockets float the mouth of the pipe above the surface of the water. Once the mouth of the pipe is “high and dry” the floating force increases.

There are “weep holes” in the ribs on pipe. The ribs will fill with water when the pipe is buried in saturated ground.

The weep holes are very small and the ribs fill slowly. When the pipe is suddenly submerged in water, the air cannot escape from the ribs fast enough to avoid floating.

Poke more and larger holes in the ribs if you plan to leave a section of uncovered pipe submerged in the water. Put a least two holes in each rib and make sure one hole is near the top of the pipe to let the air out. Another method is to use a circular saw to make a couple of shallow cuts through the top of the ribs along the exposed section of pipe.

Anchor the pipe by driving long rebar pegs or fenceposts into the ground adjacent to the uncovered pipe and bind the pipe securely to the anchors counteract the floating force.

Be carful to avoid floating of pipe extensions from inline structures when leaving an uncovered stub in the pond!

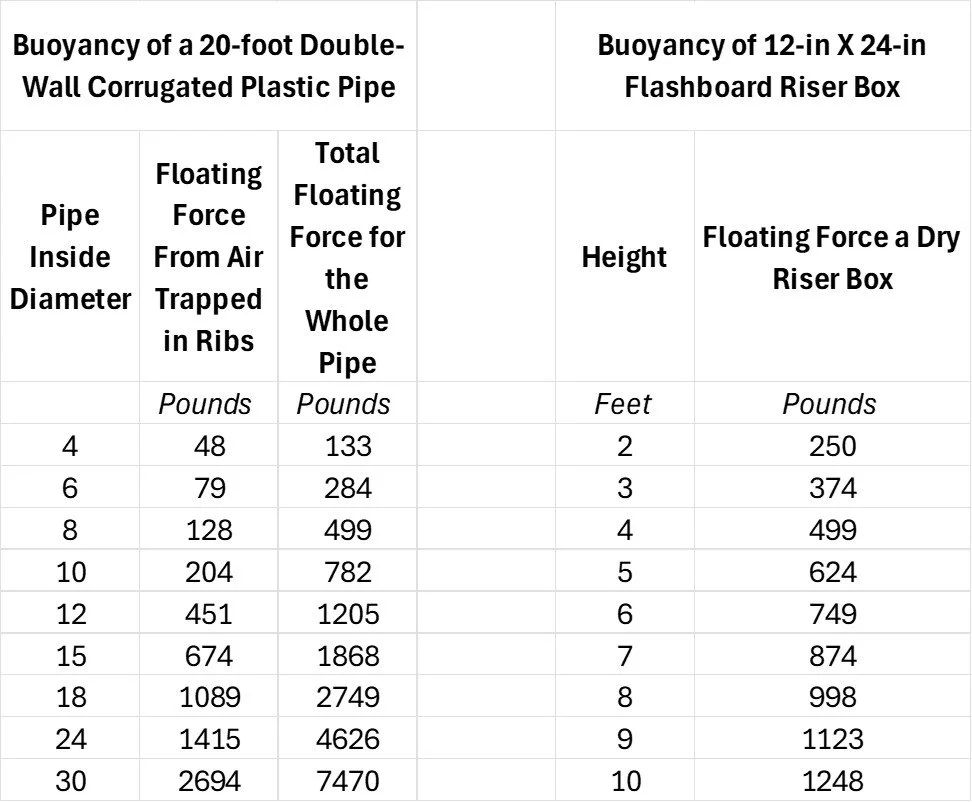

Tabulated values for the floating forces encountered by various diameter pipes and a standard 12-inch X 24-inch flashboard riser box.

Bigger boxes will have higher floating forces.

Add the value for your pipe diameter and box height together to get the total floating force — it will be surprisingly large.

A couple feet of earth covering the pipe easily overcomes the floating forces.

The weight of the flashboard box plus the soil pressing against the riser box and resting on top of the base lip and ribs overcomes the floating forces on short risers. Longer risers need additional support to avoid floating.